So you’ve found a mobile home dealer you are comfortable with, bought your home on a square deal, found a site, and checked the zoning laws. Give yourself a pat on the back! You’ve come so far already. Now, things get exciting. You’re ready to have the mobile home installed on your home site. If everything goes well, you’re just a few short weeks away from moving into your new home.

So you’ve found a mobile home dealer you are comfortable with, bought your home on a square deal, found a site, and checked the zoning laws. Give yourself a pat on the back! You’ve come so far already. Now, things get exciting. You’re ready to have the mobile home installed on your home site. If everything goes well, you’re just a few short weeks away from moving into your new home.

We also have a shorter article on Home Installation here.

Manufactured homes installation is a critical stage in the mobile home-buying process. Your home may be flawless when it arrives from the factory, but if it is not installed properly, none of the quality workmanship or top-of-the-range upgrades will matter. Improper manufactured homes installation can lead to leakages, bowing, warping and other problems that can be expensive to repair and can seriously impact your home’s lifespan and durability.

Related: Choosing the Land to Install Your Mobile Home On

This is one area where finding the right installers and contractors really pays off. You need people you can trust to do a professional job in a timely manner.

The aim of this guide is to help you become a proactive and informed mobile home owner who understands the installation process and knows how to ask the right questions so you can protect the investment you’ve just made – and avoid costly problems.

First Things First: Don’t Try to Install Manufactured Homes Yourself!

Installing mobile homes is hard and dangerous work – you’ll need a professional manufactured homes installer to do the job. In most states, it’s unlawful for any person to occupy a mobile home unless the home has been installed by a HUD-certified installer. The HUD ticket means that the installer is specially trained to install your home in compliance with the manufacturer’s detailed instructions, HUD codes, and local building codes.

Installing mobile homes is hard and dangerous work – you’ll need a professional manufactured homes installer to do the job. In most states, it’s unlawful for any person to occupy a mobile home unless the home has been installed by a HUD-certified installer. The HUD ticket means that the installer is specially trained to install your home in compliance with the manufacturer’s detailed instructions, HUD codes, and local building codes.

A professional installer or “set-up” company may also offer site preparation services. This is preferred as one crew performing both functions can result in a seamless flow of services on site. However, because of their specialist certification, you’ll also find installers who perform set-up tasks only, leaving the work of site preparation, laying the foundations, bringing in utilities, laying the landscaping and so on, to general contractors. This isn’t a problem as long as everyone communicates, everyone knows their distinct responsibilities, and everyone knows where the buck stops. When things go wrong, it’s usually because the work is not properly coordinated and overseen.

A reputable mobile home dealer can provide you with a list of recommended general contractors (GCs) and HUD-certified set-up contractors to help get your home completed on site and ready for occupancy. Some mobile home dealers are HUD authorized to install modular homes and mobile homes themselves. This is a good option as it minimizes the number of people you have to deal with and avoids a contractor being able to put the blame on someone else.

How Much Will Manufactured Homes Installation Cost?

Sometimes, the price of mobile homes includes the cost of installation. Be clear on this before you sign the sales contract. If installation is not included in the price, you’ll be responsible for hiring the set-up crew and paying their fees. What sort of costs are we talking about? You won’t be surprised to hear that it depends on the providers involved and the complexity of the installation.

For example, if you’re moving into a park homes community, there probably isn’t a great deal to do beyond setting up your home and hooking up to the existing utilities. The community manager will probably take care of site preparation.

On the other hand, if you’re moving onto undeveloped land with no connection to city services, the task becomes considerably more complex. To give you an example, someone installing a new double-wide on an acre of semi-rural land is looking at the following tasks:

Site excavation, laying foundations, well drilling, designing and installing a septic system, digging trenches for utilities, water, TV etc, blocking, leveling and anchoring the home, laying a moisture barrier, sealing end seams and roof joints, connection to water, electricity and septic system, placing a propane tank and plumbing the gas connection to home, installing dry wells, gutters and downspouts, constructing skirting around the home’s perimeter, finishing interior trim, laying carpets, installing air conditioning unit, telephone and TV cabling services, constructing the driveway, site inspections per HUD requirements and local building codes, trash clearance, and cleaning to leave the home move-in ready.

The job will involve potentially dozens of people on site, all of whom will need paying. Setup costs can run anywhere from $1,500 for single wides ($3,000 for double wides) to $20,000 or more, depending on the size of the job. To make sure prices and services are in line, solicit bids from at least two installation crews. Ask each to meet you at the site so they can get an idea of where you plan to place your home, and can quote your job based on local conditions, regulations, and any job-specific considerations that are required.

Related: How Much Does it Cost to Move Your Mobile Home?

A Word About Warranties

All mobile homes’ manufacturers should offer a written warranty that covers the structural workmanship of the home, as well as factory-installed plumbing, heating, electrical systems and appliances. Be sure to get the lowdown on warranties before you buy. Here is Home Nations warranty.

There are several companies that offer more general home warranties for your mobile home that you can read about here.

Manufacturer warranties DO NOT cover the installation of the home. Coverage should be available from the person who sets up and installs your home so do check before you hire the set-up crew. If damage occurs from a faulty set-up, your new-home warranty could be affected. Get written proof of the installer’s qualifications and make sure he is fully certified and bonded before you hand over the money.

Get Everything in Writing!

For every set-up installer, GC or sub-trader you hire, be sure to get in writing:

What services are provided: Specify the services such as site clearance, foundations, utilities, septic tank, HUD-certified installation and so on. Be sure to include the level of finishing work included in the contract such as joining the carpet and molding on a new double wide, and siding work on the exterior. Be very specific about what you want done, especially if you want additional services such as building a garage or landscaping. If you want topsoil laid, get it in writing. If you want grass seeds sown, get it in writing.

How those services will be provided: Write down the steps for installation with a timeline for finishing important tasks. This ensures that the work is done in a timely and correct fashion.

The payment schedule: Be clear when payments will be made for specific tasks. If you have a construction loan, your lender will spell out this element.

Warranty coverage: Write down who is providing the warranty and what the warranty will cover. If there’s no written warranty, you probably want to find another installer.

Retention provision: A legal retention is a clause in the contract that lets you hold back or “retain” 10 percent of the project costs until the contractor has fixed any problems noted during the final inspection or walk through, and has delivered the warranty. This is standard procedure in the construction industry and incentivizes the set-up crew to complete the project to your satisfaction.

Although some mobile home owners think that an installation contract is not necessary, it really is your best protection against unexpected charges and misunderstandings about who is responsible for what.

Preparing the Home Site

Before your home is delivered, you must make sure that the site has been prepared and is accessible. It’s a good idea to have the set-up crew visit the site before they quote for the job, so you’re both aware of any special requirements you might have to consider.

Here’s a checklist of the common site-preparation issues:

Access: The heavy delivery truck transporting your home must be able to get to the home site easily. Depending on the location of your site, you might have to fell trees, take down fencing, use a bulldozer to widen access lanes, or contact the utility company to remove wires in order to accommodate the load size of the home being delivered. If transportation is included in your home price, it’s usually the dealer’s responsibility to plan the route to the home site. Otherwise, you’ll need to sort this out yourself alongside the transporter and GC.

Site clearance: The site area must be cleared of trees, shrubs, rocks and debris in areas where footings are to be placed. It’s important to preserve some trees and shrubs for shade, wind breaks and visual screening so you’ll need to plan the landscaping before you start clearing the site.

Grade the site: The site must be properly graded and sloped so that rainwater will drain away from the mobile home and not pool under it. Where walls or other physical conditions prevent grading, the site will need providing with drains or swales to manage water runoff.

Soil conditions: The soil should be packed down and level so the foundation won’t shift around because the ground is soft. You’ll also need to determine the site’s soil bearing capacity as this will impact the type and size of foundations.

Provision for temporary needs: Consider the location for portable toilets, dumpsters, parking, and delivery vehicle drop-offs while the crew is on site.

You might be able to do some of the site-preparation work yourself to reduce costs, for example, removing shrubs and trees. However, most site preparation work requires a professional and should be built into the quote from your installer or GC. Take care when doing any preparation work yourself, as mistakes could do damage to your home that’s not covered by the manufacturer’s warranty.

Laying the Mobile Home’s Foundations

Constructing the foundation on which your home will be placed is the major task of site preparation. There are two basic types of foundation: those to which the home is permanently affixed, and non-permanent foundations. Chances are, you will not be able to choose the foundation type. Local building codes, lenders and park communities increasingly are specifying which type of foundation must be laid, and manufacturers may reduce their warranty coverage unless you follow their specifications.

Weather and soil conditions in your area are other major considerations. Most jurisdictions have rules regarding the depth of clearances under the home, minimum slab thickness, frost-depth requirements, pier pad spacing and so on to account for local conditions. A good GC and set-up crew will know these requirements inside and out and will get the necessary building permits.

In short, there isn’t really much leeway in selecting your foundation, but you should make your GC aware of any lender or park requirements.

Foundation Types

Here are some of the options:

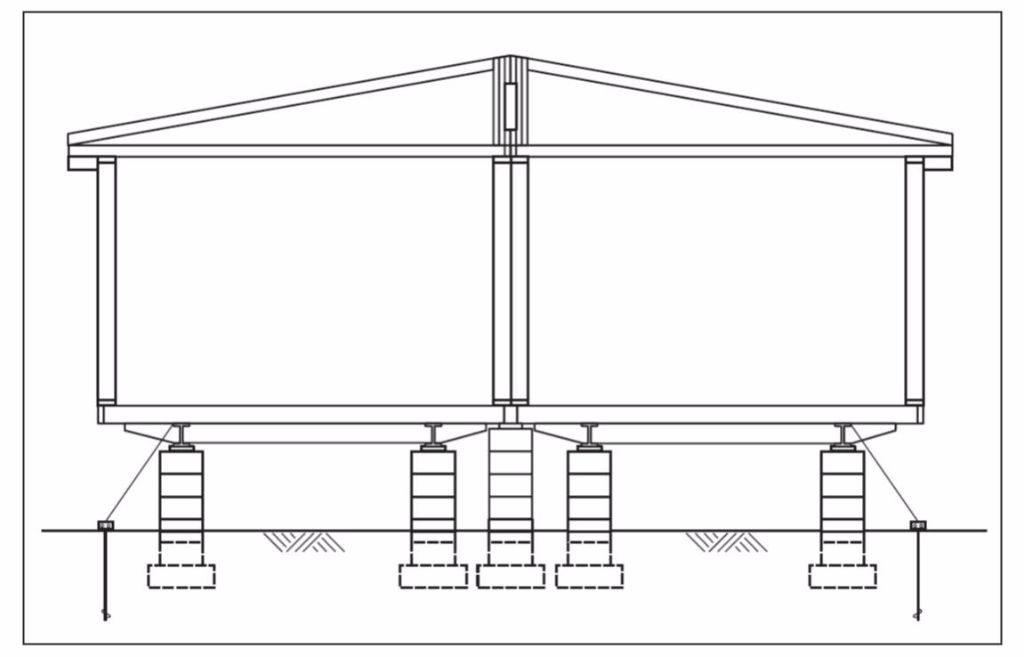

Piers and Beams: Pier-and-beam foundations are a shallow, non-permanent foundation constructed of cinder blocks placed at intervals beneath the undercarriage frame of the mobile home and along the marriage line if you’re installing a new double wide. Good in mild climates where the ground does not freeze, pier-and-beam foundations are the least expensive option, with costs coming in at around $1,000 for single-wides and around $2,000 for small double-wides. The blocks may settle over time, however, causing the ground to shift. You may need annual re-leveling.

Block and Footing: The same as pier-and-beam except the masonry blocks are placed on concrete footings so the foundation is significantly more stable. Settling can still occur, however, and since the home is unanchored, it may be vulnerable to high winds. The cost is slightly higher, too at around $1,500 to $2,000 in addition to the cost of a pier-and-beam foundation.

Floating slab: The most popular type of permanent foundation, a floating slab is exactly what the name suggests – a concrete slab, around 6 inches thick, that is laid on top of the ground. The slab usually contains a steel reinforcement bar (rebar) or bolts installed into the concrete which serve as an anchor point. When the slab is cured after around a week, the home is rolled on and tied down to the anchor points in the concrete. Variations include:

- A pit-set foundation which lays the floating slab in an excavated shallow pit, a foot or two below ground level. Walls are poured around the perimeter to be even with or slightly higher than ground level. The advantage of a pit-set foundation is that you get a much larger crawl space.

- A roll-on foundation which recesses the pit, often five feet below grade. Reinforced walls are then poured so the home’s floor can be positioned at ground level.

A floating slab foundation is economical to use in areas that are prone to frost heave and gives a very secure, stable and permanent foundation. It will take around 14 days to install, however, and is more expensive than non-permanent foundations. Expect to pay anywhere between $6,000 and $15,000 for a standard double wide.

Basement foundation: A popular option for modular homes with inside basement access doors, this specialist type of foundation provides a basement area that can be plumbed, wired and heated as additional living space. Installation requires a crane to drop the home into the foundation pit a section at a time, which makes this the most expensive foundation option. Expect to pay around $12,000 for a small home or $25,000 for a large home, with regional differences. You’ll need to hire a contractor with expertise in this type of home placement.

Related: Crane Setting a Mobile Home

Anchoring Mobile Homes

With certain foundation types, you’ll need to tie down or anchor the frame of your home to the foundation to keep it from shifting around in high winds and earthquakes. Most states have very strict anchoring requirements that boost the home’s safety and durability. Anchoring must comply with manufacturer’s requirements and local building codes or you’ll invalidate your manufacturer’s warranty. Make sure that anchoring is included in the installation contract – don’t attempt to do this yourself!

Manufactured Homes Installation and Set Up

From the moment your home is placed on its foundation, you’re looking at around a week or two before move in if your site work is minimal, or around six weeks if you’re developing raw land. Expect the home site to get busy. While your GC is getting on with installing utilities and septic systems, the installation crew will set up the home itself. This involves compliance with over 100 HUD code requirements and potentially hundreds more set by the manufacturer.

Legal Requirements for Installing Mobile Homes

The method for installing your manufactured home is mandated by three sets of installation and setup procedures: the Model Manufactured Home Installation Standard (commonly referred to as the national “HUD Code”), state HUD codes, and the manufacturer’s requirements. Think of the three codes as a pyramid. At the bottom of the pyramid, the national HUD code sets out a basic level of regulation, including such matters as foundations, tie points, plumbing, ductwork, and electrical systems. State codes then add extra checkpoints based on average climate and soil conditions in the region.

The manufacturer’s installation manual trumps all other codes. By law, each manufacturer must hand over detailed installation requirements for every make and model of home. The requirements should meet all HUD standards but are usually much more detailed and will have higher regulations that your installation crew must follow. Your manufacturer’s warranty may be voided unless the installation follows the manufacturer’s manual to the letter.

Related: Manufactured & Modular Home Building Codes

Installation Sequence and Timeline

While each installation is different, the following sets out a generalized version of the typical task sequence for setting up a new double wide after the foundations have been laid. Installing single wide homes follows a similar sequence but is typically more straightforward since there’s only one section. It’s a GC’s job to schedule tasks, workers and subcontractors in proper sequence when your home is finished at the factory.

- Remove packing materials that protected the home during shipping. Inspect the home and all provided materials, appliances and equipment immediately upon delivery. Report any damage or shortages to the manufacturer. If there has been any damage during transportation, it’s usually up to the transporter to fix it before installation.

- Install polyethylene sheeting or other moisture retarder over the ground where required by manufacturer’s instructions or local building codes

- Position the first (heaviest) section on its foundation. Using a combination of hydraulic jacks, rollers and winches, move the section into its final position and remove the running gear. You’ll need a crane to position the home if you’re using basement foundations.

- Repeat with the second section. Square it with the first section.

- Block and level the home, making height adjustments as necessary to precisely align the floors, roof and intersecting walls. Fasten or “marry” each section together per manufacturer’s instructions and HUD codes.

- Anchor the home to its foundations.

- Backfill against the foundation wall to the height of the waterproofing, taking care to not damage the drainage system.

- Install gutters and downpipes.

- Connect to water, septic tank and utilities.

- Connect to heating and ventilation ducting. Make all crossover connections between the sections including electrical, doorbell, telephone and intercom wires, and plumbing.

- If the home has a basement, construct the basement stairs in compliance with the local building codes.

- If the home has a hinged roof that has been folded for shipping, seal the roof along the ridge line. Finish the roof by shingling over the ridge cap.

- Complete inside drywall. Seal the marriage line between the sections along the ceiling and floor. Repair stress cracks caused by transportation

- Install matching trim.

- Pressure test the water system and perform a power check; test appliances and smoke alarms.

- Install steps with handrails, as appropriate.

- Install or finish the carpeting.

- Install loose items such as drapes, blinds, mirrors, closet shelves and hardware.

- Remove trash. Vacuum the home and give it a thorough cleaning, leaving it ready for occupancy.

During the final stages of your home’s installation, your GC will also be busy, backfilling trenches, laying driveways and attending to additional matters like landscaping or installing a garage or deck if you’ve requested them. As you can see, there’s a lot to do – it’s not unusual for a manufacturer’s manual to run to 150 pages!

This is an exciting time for you. For several days or weeks your home site has looked like a chaotic building site, now everything comes together and your home is nearly ready for you. We understand that you’re anxious to move in. There’s just one final stage of the process to make sure that your home meets the many technical and regulatory aspects of an installation.

Final Walk Through and Building Inspection

When problems occur with a mobile home installation, it’s usually because the homeowner has been pressed into signing the final inspection ticket before the home is completely installed and finished. Signing off on a home installation usually activates some contractual small print and releases the set-up company from liability if things go wrong.

Before you sign anything, meet with the installers and conduct a final walk through of the home. This is an exciting moment – if everything goes well, you’re about an hour away from getting the keys. It’s also your only opportunity to open drawers, flip switches and generally note any scratches, abrasions, faults, dents, chips, and other shortcomings with the home. The manufacturer’s manual usually contains a checklist to help with your inspection. It’s helpful to have this with your during the walk though.

Even if the home looks good on the inside, there could be structural issues that a homeowner could not possibly see with the naked eye. Hidden problems with the downspouts or grading, for example, could cause massive water ingress leading to warping and buckling sometime down the road. A faulty foundation could cause the home to settle unevenly and might have to be completely rebuilt if it isn’t up to the job.

The single most effective way to detect “hidden” problems is by having the home inspected by an independent building inspector who is not affiliated with the setup crew or the mobile home dealer, before you sign the release paperwork. In most states, the county inspector is required to make an inspection and verify that the installation meets state minimum requirements. You won’t be permitted to move in until the home passes inspection and the inspector issues a certificate of occupancy. This also triggers a notice to the utility company to activate power. Your set-up crew will arrange for state inspection since it is ultimately their responsibility to ensure the installation has been completed in compliance with state regulation.

If your jurisdiction doesn’t require inspection – and even if it does – it’s worth hiring your own home inspector. A third-party inspector goes beyond code requirements and looks at the quality of the installation work. Discovering snags and problems early means you can get them fixed before the setup crew leaves the site, and within the warranty time limits. Pricing varies from $200 to around $400 but hands down, hiring a home inspector is the best money you’ll spend for assuring the longevity and safety of your home.

Go Forth and Move In!

Home installation and setup is not as easy as it might appear but it’s a maze that thousands of homeowners successfully navigate every year. We have prepared this guide to help you understand the installation process and to follow it successfully. If there’s one takeaway, it’s that everything hinges on hiring the right crew. Be sure to check with your state office that deals with manufactured home installation so you know what to expect from your set-up crew, hire reputable contractors, and get the important details in writing. Do that, and everything else should fall into place.

Good luck, and enjoy your new home!